Products

High quality full automatic vertical volumetric granule sachet packing machine

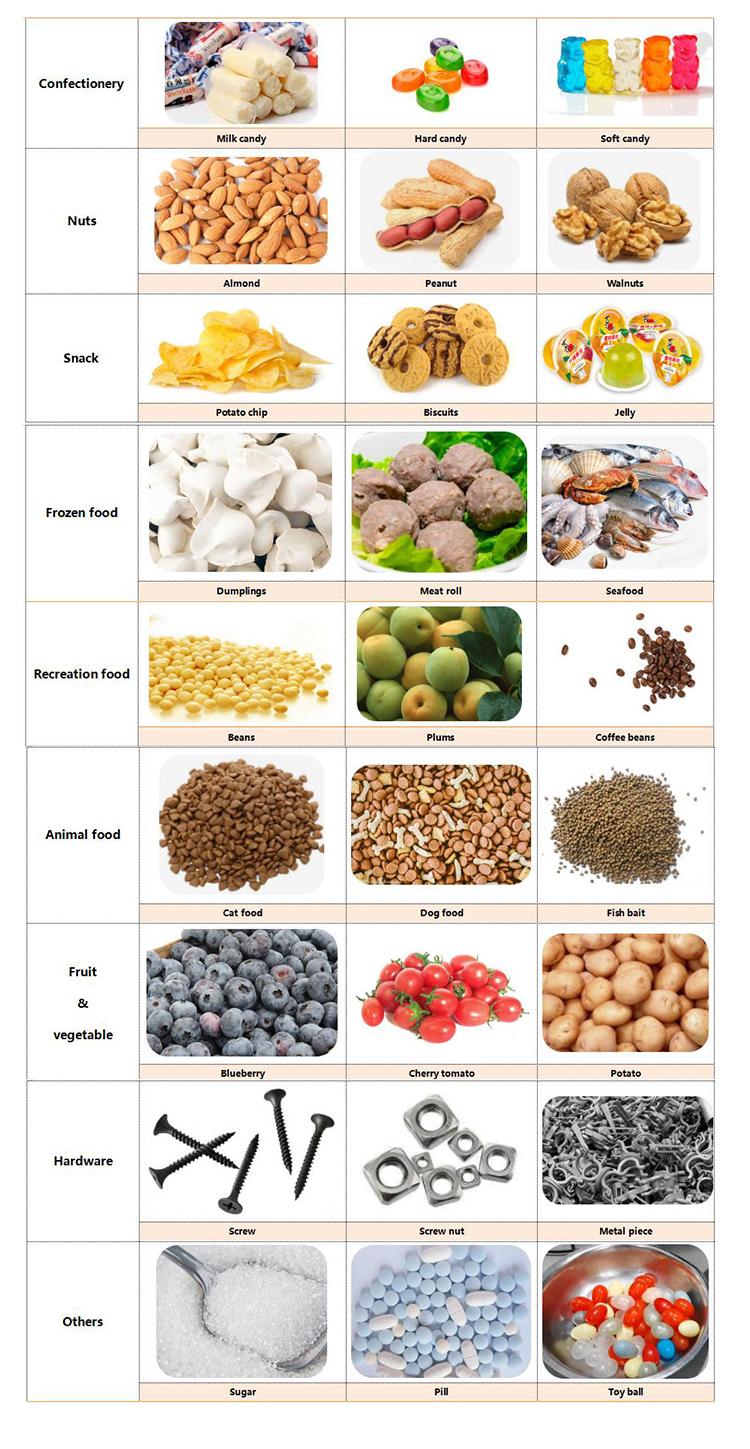

Application

Apply for regular granular packing, such as sugar, soybean, rice, corn, sea salt, edible salt and plastic products, etc.

Parameters

|

Technical Specification |

|||

| Model | ZH-180PX | ZL-180W | ZL-220SL |

| Packing Speed | 20-90Bags / Min | 20-90Bags / Min | 20-90Bags / Min |

| Bag size(mm) | (W) 50-150

(L) 50-170 |

(W):50-150

(L):50-190 |

(W) 100-200

(L) 100-310 |

| Bag making mode | Pillow bag, Gusset bag , Punching bag, Connecting bag | Pillow bag, Gusset bag , Punching bag, Connecting bag | Pillow bag, Gusset bag , Punching bag, Connecting bag |

| Maximum width of packing film | 120-320mm | 100-320mm | 220-420mm |

| Thickness of film (mm) | 0.05-0.12 | 0.05-0.12 | 0.05-0.12 |

| Air consumption | 0.3-0.5m3/min 0.6-0.8MPa | 0.3-0.5m3/min 0.6-0.8MPa | 0.4-0.m3/min 0.6-0.8MPa |

| Packing Material | laminated film such as POPP/CPP, POPP/ VMCPP, BOPP/PE, PET/ AL/PE , NY/PE, PET/ PET |

laminated film such as POPP/CPP, POPP/ VMCPP, BOPP/PE, PET/ AL/PE , NY/PE, PET/ PET |

laminated film such as POPP/CPP, POPP/ VMCPP, BOPP/PE, PET/ AL/PE , NY/PE, PET/ PET |

| Power Parameter | 220V 50/60Hz 4KW | 220V 50/60Hz 3.9KW | 220V 50/60Hz 4KW |

| Package Volume (mm) | 1350(L)×900(W)×1400(H) | 1500(L)×960(W)×1120(H) | 1500(L)×1200(W)×1600(H) |

| Gross Weight | 350kg | 210kg | 450kg |

Function and Characteristic

3)A variety of automatic alarm protection functions to minimize losser.

4)Flat cutting, pattern cutting, linking cutting can be realized by changing the tools;easy operation with smooth bags.

5)Bag-making equipment can be changed according to specific requirement of customers and products.

6)Optional English or other languages screen display, easy and simple operation. Both packaging speed and bag length can be set with one click.

7)All machines have CE certification.

8)According to customer product requirements,can be customized to add thermal transfer printer, gas-filled device, angle-of plug-in device and punching device.

Details

FAQ

1.How to find a solution suitable for my product? Tell me about your product details:

1. What kind of product you have.

2. the size of your product.

2.How easy is it to operate packaging equipment?

The good news is that as long as your packaging system isn’t hyper-customized, the equipment is pretty easy to use! Most of our equipment does not require advanced technical knowledge to operate.

3.How much does packaging equipment cost?

There is no quick, easy answer to this question. Packaging machinery is specific to the customer, so arriving at ‘standard pricing’ isn’t usually practical. Pricing largely depends upon your unique needs, such as the products you want to package, the speeds you would like to achieve, your sizes or the complexity of your process.