Driven by the wave of industrial automation, the intelligence and precision of packaging machinery have become inevitable trends in industry development. ZONPACK, a technical pioneer with 15 years of experience in the packaging field, recently launched its new-generation intelligent labeling machine. This device has not only attracted industry attention for its high precision and flexibility but also redefined the new standard for efficient labeling through its globally integrated configuration and innovative design. This article delves into the unique value of this equipment from three dimensions: technology, application, and service.

I. Technological Breakthrough: Global Configuration Drives Precision Labeling

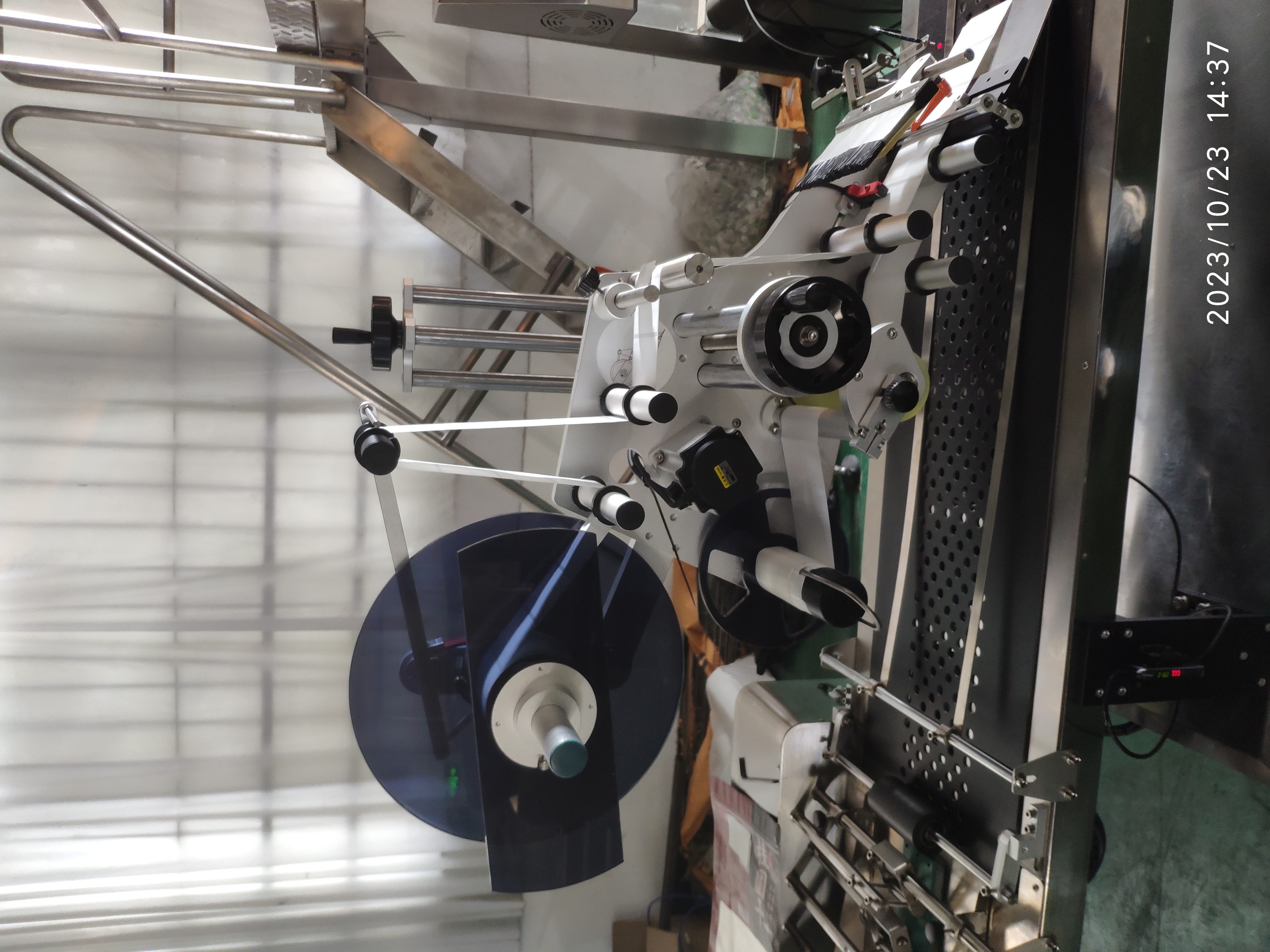

The core performance of a labeling machine depends on the synergy between its electrical system and mechanical structure. ZONPACK’s new-generation labeling machine integrates top-tier global hardware resources to build a technical foundation that combines stability and intelligence:

1. Internationally Branded Core Components

- Control System: Utilizes Delta’s DOP-107BV Human-Machine Interface (HMI) and DVP-16EC00T3 PLC controller from Taiwan, ensuring smooth operation and strong anti-interference capabilities.

- Drive System: Features the servo motor (750W) paired with the KA05 servo driver, achieving labeling accuracy of ±1.0mm, far exceeding industry standards.

- Sensing Technology: Combines Germany’s Leuze GS61/6.2 inspection sensor and Japan’s Keyence FS-N18N positioning sensor to accurately identify material positions, enabling zero-waste production with “no object unlabeled, no label unapplied.”

2. Modular Design Enhances Adaptability

The machine supports material lengths of 30-300mm and label sizes of 20-200mm. By quickly replacing the label-overlay mechanism, it can extend to complex scenarios such as curved or uneven surfaces. Its innovative “three-rod adjustment mechanism,” based on the principle of triangular stability, simplifies debugging and reduces product changeover time by over 50%.

II. Scenario Coverage: Flexible Solutions from Standalone Equipment to Production Line Integration

ZONPACK’s labeling machine emphasizes “demand-driven flexible production,” with broad application scenarios and high scalability:

- Cross-Industry Compatibility: Suitable for flat-surface labeling in food, pharmaceuticals, electronics, and other industries (e.g., cartons, books, plastic boxes). Optional modules also support specialized scenarios like circular labeling for medical bottles or anti-counterfeit label positioning for electronics.

- Integrated Smart Functions:

- Automatic Correction and Anti-Slip Design: Eccentric wheel traction technology combined with a label deviation correction mechanism ensures no label displacement or detachment during high-speed operation.

- Digital Management: A 10-inch touchscreen with Chinese/English interfaces integrates production counting, energy consumption monitoring, and self-diagnosis functions, enabling refined production management.

Additionally, the machine operates independently or integrates seamlessly with production lines, offering compatibility that supports gradual upgrades from single-point optimization to full-line intelligence.

III. Service Ecosystem: Full-Lifecycle Support Empowers Customer Value

In the industrial equipment sector, after-sales service is a critical factor in customer decision-making. ZONPACK provides value beyond the equipment itself through a “delivery-maintenance-upgrade” trinity service system:

1. Efficient Delivery and Worry-Free Warranty

- Production completed within 30 working days after order confirmation.

- 12-month warranty for the entire machine, with free replacement of non-human-damaged core components.

2. Instant Technical Support

- 24 remote video guidance and fault diagnosis.

- Free equipment debugging, operator training, and periodic maintenance plans.

3. Customized Upgrade Services

For specialized needs (e.g., ultra-high-speed production lines, micro-label applications), ZONPACK offers hardware upgrades and software customization to ensure deep compatibility with customer workflows.

IV. Industry Insights: Dual Exploration of Intelligence and Sustainability

The launch of ZONPACK’s new-generation labeling machine not only highlights its technical innovation but also reflects the strategic determination of Chinese manufacturers to advance toward high-end, internationalized solutions. By integrating global supply chain resources with independent R&D, the company has shattered the stereotype of “low-cost, low-quality” Chinese equipment, winning trust from clients in over 50 countries and regions with performance rivaling European/American brands and cost competitiveness.

Conclusion

In the packaging automation sector, labeling machines, though a niche segment, are critical to product presentation and production efficiency. With its new-generation intelligent labeling machine, ZONPACK not only showcases China’s manufacturing prowess but also delivers a fresh “precision + flexibility + service” solution for the industry. Its success demonstrates that only by leveraging global resources and driving innovation through customer needs can a company maintain leadership in a competitive market.

Further Reading

- [Technical Parameters] Labeling speed: 40-120 pieces/min|Power supply: AC220V 1.5KW

- [Core Configuration] Delta PLC (Taiwan)|Leuze sensors (Germany)|Schneider low-voltage components (France)

- [Applicable Industries] Food|Pharmaceuticals|Electronics|Daily Chemicals

For detailed product information or customized solutions, contact us now!

Post time: Apr-30-2025