Products

Dried Mango Snacks Automatic Rotary Particle Packing Machine with Combination Scale

Freeze-Dried Fruit Automated Packaging System

ZH-GD8L-250 Rotary Pouch Packer + 10-Head Weigher Integrated Line

25-40 BPM | Food-Grade 304SS | Freeze-Dried Specialty

Core System Advantages

✅ High-Speed Output: 25-40 bags/minute – 50% faster than conventional lines

✅ End-to-End Automation: Elevating → Weighing → Filling → Inspection in one flow

✅ Freeze-Dried Optimization: Anti-breakage design + ±0.1g precision weighing

✅ Extended Support: 18-month full-system warranty + lifetime critical spare parts

Technical Specifications

| Key Metric | Specification |

|---|---|

| Packaging Speed | 25-40 bags/min |

| Weighing Accuracy | ±0.1-1.5g (freeze-dried optimized) |

| Multihead Weigher | ZH-A10 (10 heads × 1.6L hoppers) |

| Pouch Compatibility | Stand-up/Zipper/M-seal (100-250mm W) |

| Checkweigher Tolerance | ±1g (ZH-DW300 model) |

| Total Power Consumption | 4.85kW (220V 50/60Hz global voltage) |

| Air Supply | ≥0.8MPa, 600 L/min |

Precision-Engineered Components

1. ZH-A10 10-Head Multihead Weigher

- Micro-Weighing: Stepper motor control, 10-2000g range

- Fruit Protection: Low-impact vibration feeders

- Industrial-Grade Electronics: Fujitsu CPU + Texas Instruments AD converters

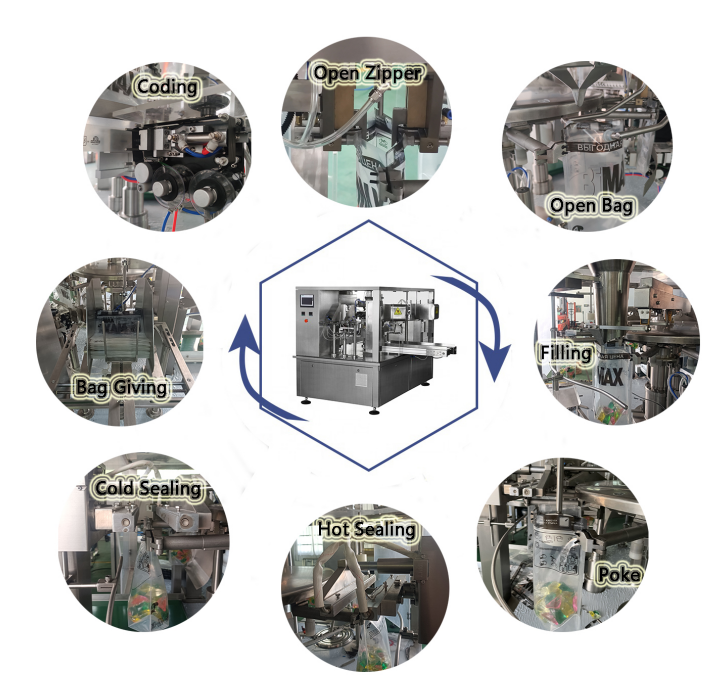

2. ZH-GD8L-250 Rotary Pouch Packer

- 8-Station Synchronization: Auto pouch opening → Dedusting → Filling → Sealing

- Powder Management: Patented dust removal system (freeze-dried powder specialty)

- Siemens PLC Control: 7″ HMI with real-time diagnostics

3. Freeze-Dried Food Modules

- Anti-Breakage Chute: Frequency-controlled gentle discharge

- Sub-Zero Operation: Certified for -30°C environments

- Hopper Temperature Control: Prevents moisture condensation

Industry-Specific Solution

Freeze-Dried Packaging Workflow

Compatible Products

- Freeze-dried fruit chunks/whole berries

- Vegetable crisps

- Instant coffee/soups

- Pet freeze-dried treats

Value Proposition

| Industry Challenge | Our Solution | Customer Benefit |

|---|---|---|

| Product fragility | 3-stage cushioning system | Breakage ↓80% |

| Powder-contaminated seals | Dedusting nozzle technology | 99.2% seal integrity |

| Cold-environment failures | Sealed bearings + moisture-proof electronics | MTBF ↑3000 hours |

Component Specifications

▶ ZH-CZ18-SS-B Bucket Elevator

- 304SS chain | 1.8L PP buckets

- VFD control | 4-6.5m³/h capacity

▶ ZH-PF-SS Work Platform

- 1900×1900×1800mm | Non-slip stairs + guardrails

- Full 304SS construction

▶ ZH-DW300 Checkweigher

- 50-5000g dynamic weighing | 60 PPM

- Automatic rejection