Products

Automatic Nuts Bottle Filling Packing Machine for Candy Jar Filling Machine

Can/Jar/Bottle Filling Machine

Product Description

This is a fully automatic packaging line, which includes automatic conveying, weighing, packaging, labeling, capping and pressing, and Bottle aluminum film sealing.

In order to get a program that is exclusive to your product. Please provide the following information: 1: Your product situation (what is the product/target weight) 2: Bottle situation (photo/size)

Application

This system is used for granular/grain/nut/particulate packaging(Here are some real-life examples)

Specification

In order to better weigh and fill your products, the design will be flexible.

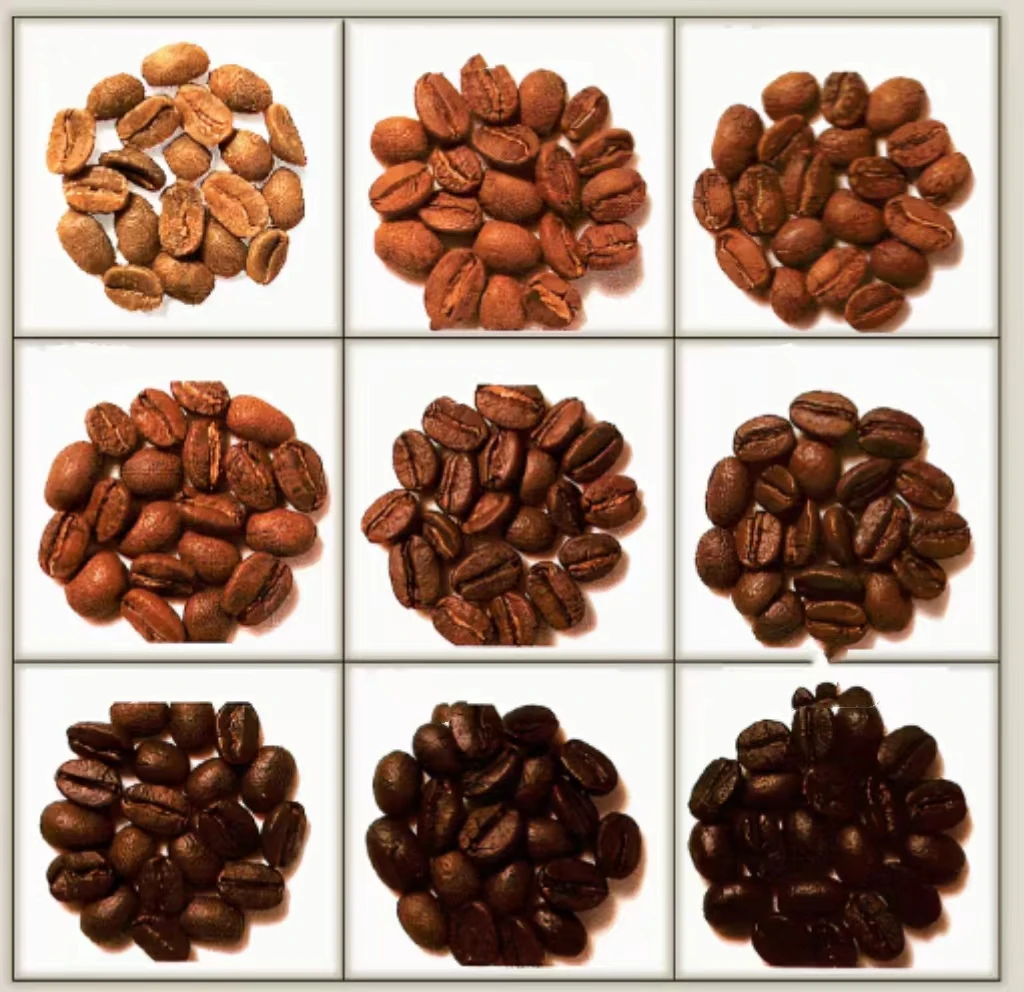

Now I would like to share with you the coffee bean program of American customers, hoping to have a certain understanding of our machine

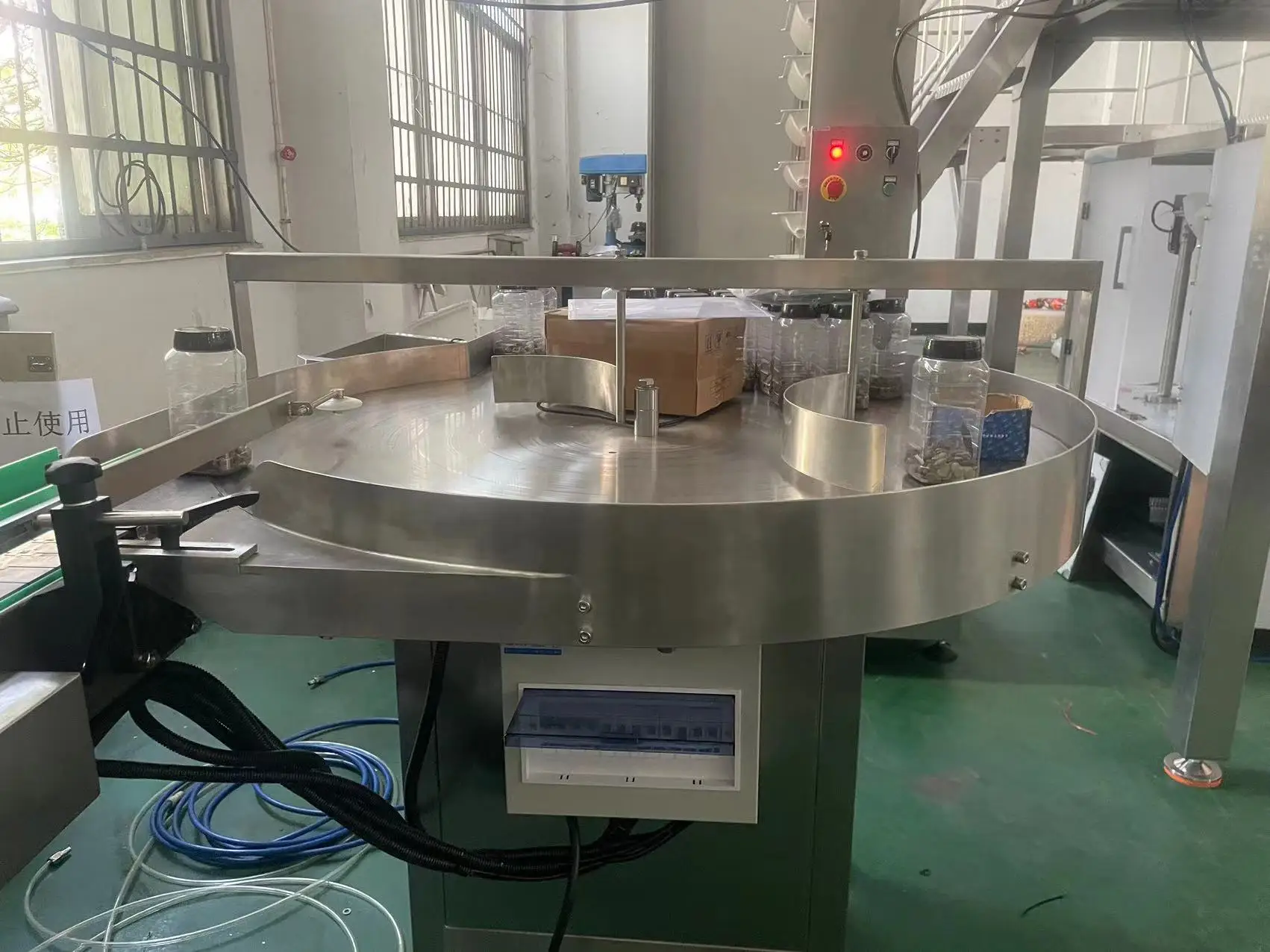

Automatic bottle collecting table

1.Turntable diameter 800mm/1200mm can customer made according to customer requirement

2.The max production efficiency reaching up to 10-100 bottles per minute according to different

bottle shape.

3.Power supply: single phase 220V, 50HZ, 0.2KW

3.Power supply: single phase 220V, 50HZ, 0.2KW

|

Applicable standards

|

10-2000ml

|

|

Applicative bottle diameter

|

φ10-φ200mm

|

|

Applicative bottle height

|

55-300mm

|

|

Production capacity

|

0-100瓶/分

0-100bottles /min. (adjustable production speed) |

|

Voltage

|

220v 50hz

|

|

Output power

|

0.2kw

|

|

Weight

|

75KG

|

can/jar Sterilizer

disinfection and cleaning of empty cans of various round specifications.

Reliable quality and simple operation,

It can be used alone or in combination with other filling lines.

characteristics:

1. Frequency conversion speed of the main engine;

2. The parts in contact with the tank are made of 304 stainless steel, which meets the requirements of food and drug hygiene.

|

it is a must-have ideal equipment for food, beverage, pharmaceutical, chemical industry,etc

|

|

|

Speed

|

1-45can/min

|

|

Size

|

diametre φ73-φ127mm /height: 80-200mm

|

Automatic Z shape conveyor mixes coffee beans and powder

1. It has advantages of large quantity and

height lifting.

2. Bucket is made with food grade PP material and stable in shape.

3. Machine can convey product continuously or intermittently.Mode can be switched freely

4. 304SS chain and 304SS frame

5.Speed and vibration amplitude are freely controlled. VFD control speed.

height lifting.

2. Bucket is made with food grade PP material and stable in shape.

3. Machine can convey product continuously or intermittently.Mode can be switched freely

4. 304SS chain and 304SS frame

5.Speed and vibration amplitude are freely controlled. VFD control speed.

(This customer conveyor also has the effect of detect metal and Mix 2 kind product)

|

Model

|

ZH-CZ

|

|

Bucket Volume (L)

|

0.8

|

|

Convey Capacitance (m3/h)

|

0.2-2

|

|

Power

|

220V or 380V 50/60Hz 0.75kW

|

|

Package Size (mm)

|

1900(L)*950(W)*1150(H)

|

|

Height for standard Machine. (mm)

|

3600

|

|

Gross Weight (Kg)

|

500

|

2/4/10/14/20/32head mutihead weigher

1.High accuracy and tailored load cell.

2.Intelligent multi-sampling stable mode, higher accuracy.

2.Intelligent multi-sampling stable mode, higher accuracy.

3.Intelligent alarm diagnosis.

4.High speed stagger dump function. 5.Modular technology, more efficient and stable 6.Modbus Industry communication protocol

|

Model

|

ZH-A14

|

|

Weighing Range

|

10-2000g

|

|

Max Weigh Speed

|

120 Bags/Min

|

|

Accuracy

|

±0.1-1.5g

|

|

Hopper Volume

|

1600ml/2500ml

|

|

Driver Method

|

Stepper Motor

|

|

Option

|

Timing Hopper/ Double door Hopper/ Dimple Hopper/ Printer/

Overweight Identifier / Rotary Vibrator |

|

Interface

|

7″/10″HMI

|

|

Power Parameter

|

220V/ 1500W/ 50/60HZ/ 10A

|

|

Package Volume (mm)

|

1680(L)×1182(W)×1268(H)

|

|

Gross Weight(Kg)

|

450

|

Automatic rotary filling machine

With a series of automatic functions such as automatic can feeding, material filling, finished product output, empty can rejection and so on.

Applicable shapes: round cans, square cans, oval cans

304SS Frame, with 12 stations,The diameter of hopper can be customized according to cans

Metal Detector

1.languages to choose, 7″standard industrial 2.Digital control main board, stable performance, automatic product setup function, visual detecting wave shape, easy to adjust. 3.Large storage space, can save product program and record of produce and alarm etc; 4.Multi-level user administration to avoid unprofessional changes parameters.

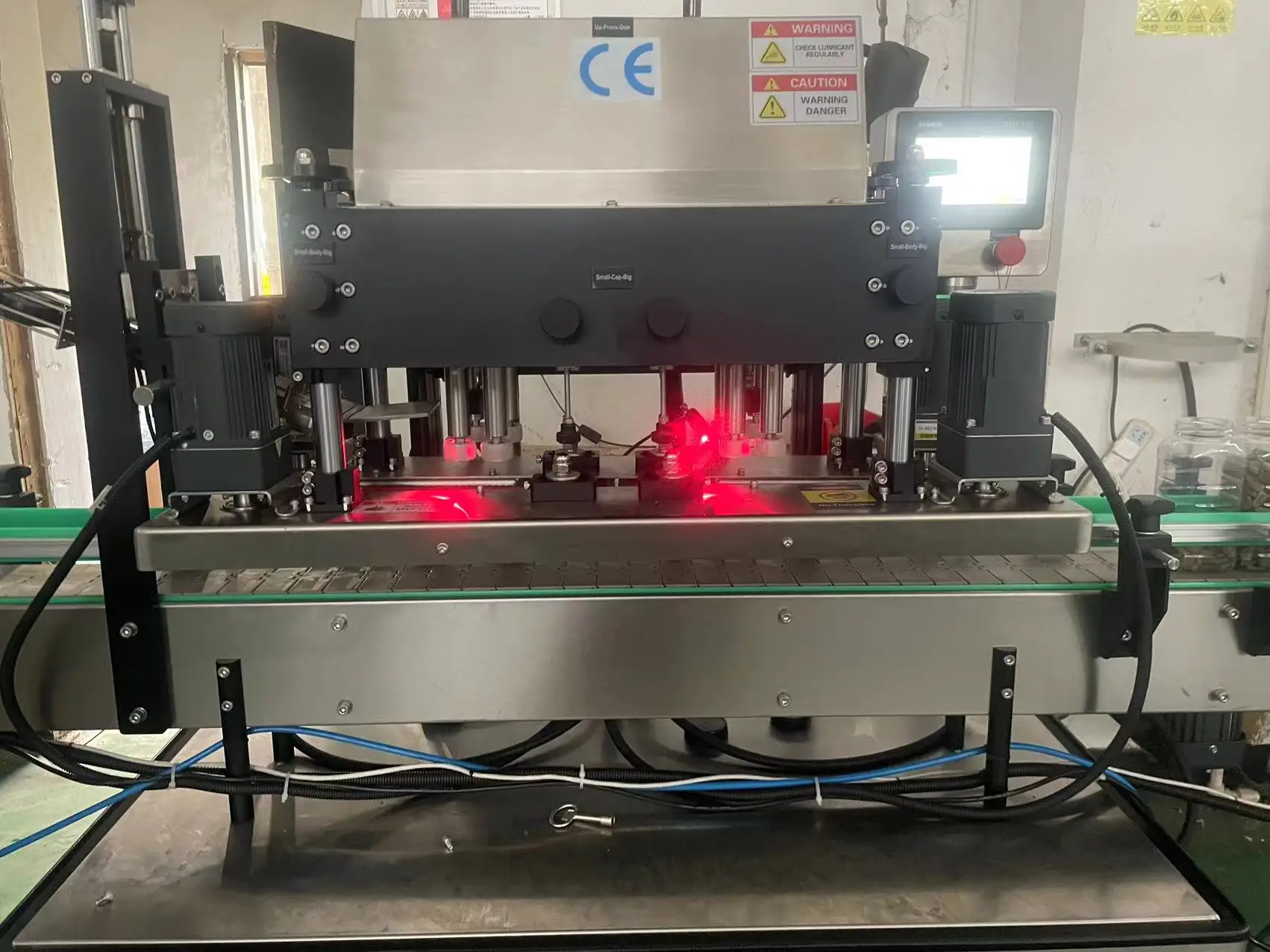

Bottle Automatic Capping Machine

1. Touch panel, feel comfortable, set up simple, beautiful and practical;

2. The speed of cap swivel is fast, compared with the normal claw capping machine, the speed of cap swivel can be increased by 3-4 times, and effectively prevent bottle body pulling, cap breakage and other problems;

3. Simply adjust the distance between the belt, the cap wheel and the height of the frame to suit the various specifications of the bottle in the applicable range without changing the parts;

4. It can be used individually, and can also be used in automatic mechanical packaging production line with filling, sealing, labeling and other equipment。

2. The speed of cap swivel is fast, compared with the normal claw capping machine, the speed of cap swivel can be increased by 3-4 times, and effectively prevent bottle body pulling, cap breakage and other problems;

3. Simply adjust the distance between the belt, the cap wheel and the height of the frame to suit the various specifications of the bottle in the applicable range without changing the parts;

4. It can be used individually, and can also be used in automatic mechanical packaging production line with filling, sealing, labeling and other equipment。

|

Model

|

ZH-XG-120-8

|

|

Capping range

|

20-120mm

|

|

Capping speed

|

60-20/min(Can be custmized 300 bottle/min)

|

|

power

|

2000W AC220V 50/60HZ

|

|

Bottle Diameter

|

30-130mm

|

|

Cap height

|

15-50mm

|

|

Bottle height

|

50-280mm

|

|

Working air pressure

|

0.4-0.6Mpa

|

|

Air consumption

|

200L/min

|

aluminum foil sealing machine

1. Stainless steel construction for using in harsh environment and easy for clean and maintenance

2. Fast speed for bulk production

3. Conveyor speed and sealing speed can be adjusted

4. Easy to use, no special train on operator required

5. Height of sealing line adjustable to accept wide range of bottle heights

6. Electric current overload, voltage overload and output overload protection