Products

Automatic Blueberry Clamshell Filler Frozen Fruit Filling Weighing Packaging Machine

|

Technical Feature For Fruits Clamshell Packaging

|

||||

|

1.This is automatically packing line , just need one operator, save more cost of labor

|

||||

|

2. From Feeding / weighing (Or counting ) / filling /capping /Printing to Labeling , This is fully automatic packing line , it more efficiency

|

||||

|

3. Use HBM weighing sensor to weighing Or Counting product , It with more high accuracy ,and save more material cost

|

||||

|

4. Using fully packing line , the product will packed more beautiful than Manual packing

|

||||

|

5.Using fully packing line , product will be more safe and clear in the packaging process

|

||||

|

6.Production and cost will be more easy to control than manual packing

|

Application Materials:

It is suitable for weighing filling packing for different products, such as nuts / seeds/candy /coffee Beans/ puffed food,frozen fresh vegetable and fruits,Strawberries, lettuce, bean sprouts, sweet peppers, potatoes, tomatoes, blueberries, virgin fruit, mushrooms, steak, chicken legs, frozen seafood video, frozen shrimp, frozen fish, dumplings, chives, broccoli.peas,carrots,etc.Even can counting or weighing and packing for the fruits and vegetables / Laundry beads / small hardware/Screw and nut.

Finished Product Package:

Plastic flip box packaging/tray film packaging/glass food canned/barrel packaging For other packaging boxes, please contact customer service for consultation!!!!!!!

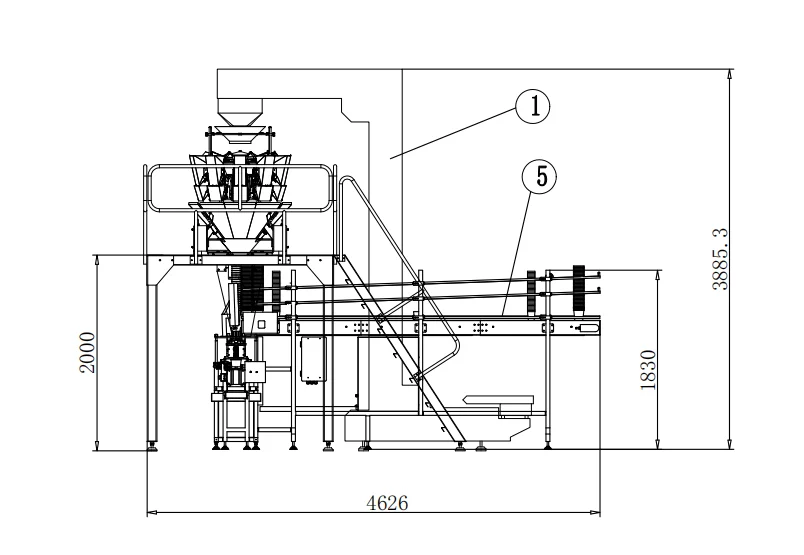

2.Descriptions of ZH-BC10 Can Filling and Packing System

|

Technical Features

|

|||

|

1. Material conveying, weighing, filling, capping, and date printing are completed automatically.

|

|||

|

2. High weighing precision and efficiency.

|

|||

|

3. Packing with can is new way of product package.

|

|

Technical Specification

|

|||

|

Model

|

ZH-BC10

|

||

|

Packing speed

|

15-50 Cans/Min

|

||

|

System Output

|

≥8.4 Ton/Day

|

||

|

Packaging Accuracy

|

±0.1-1.5g

|

||

|

System Unite

|

|||

|

a.Z Shape bucket elevator

|

Raise material to multihead weigher which controls the start and stop of the hoister.

|

||

|

b.10 heads multihead weigher

|

Used for weighing.

|

||

|

c.Working platform

|

Support the 10 heads multi weigher.

|

||

|

d.Can conveying system

|

Conveying the can.

|

||